Is Farrowing Crate Design a Constraint to Weaning Average?

June 10, 2013

Last week, we attended an open house of a new 6,000-sow farm equipped with electronic sow feeding (ESF) in large gestation pens. A tour of one of the farrowing rooms revealed 6 x 8-ft. farrowing crates with cast iron floors in the sow area and woven wire flooring in the pigs’ creep area. Crates also had rubber mats with heat lamps on both sides.

The design of the basic farrowing crate has not changed in the last 25 years. Sure, different types of flooring have been tried under the sow area – from wire, plastic, cast iron, coated-wire, tri-bar, fiberglass-coated, aluminum, etc. While most farrowing crates are 84 in. long, in some the sow’s feeder takes up part of that space. Usually, a butt bar at the rear of the crate helps prevent sows from lying on pigs during the birth process and lactation.

Over the last 10 years or so, we have urged genetic companies to focus on more total pigs born in an effort to wean more pigs/sow/year (p/s/y) and to make farrowing facilities more production and cost efficient. Each extra pig that can be weaned/sow/year can reduce the cost by approximately $1.60/pig. At 26 p/s/y, you can reduce the cost per sow by $41.60.

Naturally, as litter sizes increase, there is a greater need for more functional teats. Each pair of teats added to the underline of a female generally increases the length of the female’s body about 4 in. An increase from 10-12 nipples/female to 14-16 nipples/female means they will be 8-12 in. longer.

Like what you’re reading? Subscribe to the National Hog Farmer Weekly Preview newsletter and get the latest news delivered right to your inbox every week!

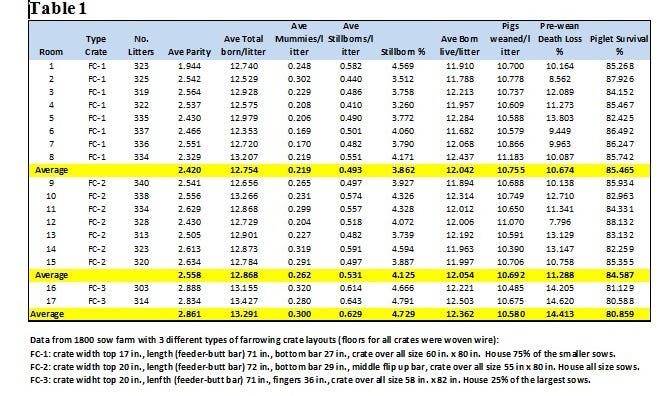

One farm we work with has three different types of farrowing crates. They allowed us to pull some farrowing data from their farm records for the last 16 months of farrowing data. Table 1 summarizes the performance data from the different crate designs:

· FC-1 farrowing crates are in rooms 1-8; crates are 17 in. wide at the top and the length from feeder to butt bar is 71 in.; bottom bow bars are 27 in. wide; overall size of the farrowing crate is 60 x 80 in. (5.0 x 6.8 ft.). Since these crates are smaller, 75% of the smaller females are placed in them.

· FC-2 crates are in rooms 9-15 with a crate width of 20 in. at the top; length from feeder to butt bar is 72 in.; bottom bow bars are 29 in. wide; overall size of the farrowing crates is 55 x 80 in. (4.6 x 6.8 ft.). These crates have a middle flip up bar to restrict the sows as they lie down. All sizes of sows are placed in these crates.

· FC-3 represents the final two rooms; crate top width is 20 in., length from feeder to butt bar is 71 in. These crates have fingers that are 36 in. wide at the bottom; overall size of the crates is 58 x 82 in. (4.8 x 6.8 ft.). About 25% of the largest sows are placed in these crates to farrow.

Table 1 shows more than 300 farrowings per room. Average parity for FC-1 crates is 2.42, FC-2 crates is 2.56, and FC-3 crates is 2.86. There is some bias in the data with younger parity sows in room FC-1 and older parity females in room FC-3.

Total pigs born ranged from 12.75 to 13.29 pigs/litter; stillborns/litter was 3.86% in FC-1, 4.13% in FC-2 and 4.73% in FC-3 – remembering that 25% of the farrowings are the larger females.

Pigs weaned/litter averaged 10.76 pigs in FC-1, 10.69 pigs in FC-2, and 10.58 pigs for FC-3. Pre-weaning death loss was highest in FC-3 with 14.41%, followed by 11.29% in FC-2 and 10.67% in FC-1.

A few years ago, we put together an equation we call “piglet survival,” which is simply: 100 – (stillborn % + preweaning death loss %). There was a difference of 4.61% in piglet survival from FC-1 to FC-3. For a 2,500-sow farm weaning 25 p/s/y, that improvement in piglet survival would add 2,880 pigs to their annual production.

This farm attempted to place some females in certain farrowing crates to reduce piglet losses, although it did not result in more pigs saved.

The new 6,000-sow farm we toured two weeks ago was equipped with 6 x 8 ft.-farrowing crates with top bar width at 22 in., the bottom bow bars width of 29.5 in., and height of crate at 42.5 in. The farrowing crates have the flip up bars on the middle bar to restrict the sow as she lies down. Farm managers said they plan to wean more than 16 pigs/ litter at about 20 days of age in the near future.

If your farm is struggling to save more pigs/litter, you may need to review your facilities, as well as the people and the sows. As farms continue to raise the bar for producing more pigs/sow/year, they may need to make some changes to meet their goals. If you are remodeling or building new, the constraints to saving more pigs/litter could include the size of your farrowing crates.

Previous Production Preview columns can be found at www.nationalhogfarmer.com.

Key Performance Indicators

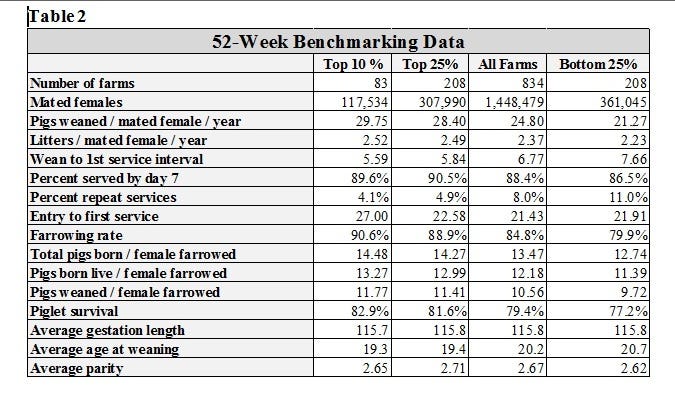

Tables 2 and 3 (below) provide 52-week and 13-week rolling averages for key performance indicators (KPI) of breeding herd performance. These tables reflect the most current quarterly data available and are presented with each column. The KPI’s can be used as general guidelines to measure the productivity of your herd compared to the top 10% and top 25% of farms, the average performance for all farms, and the bottom 25% of farms in the SMS database.

If you have questions or comments about these columns, or if you have a specific performance measurement that you would like to see benchmarked in our database, please address them to: [email protected] or [email protected].

You might also like:

If You Could Get Two More Pigs/Litter, Could You Save Them?

Shorten Wean-to-First-Service Interval to Boost Farrowing Rate, Total Pigs Born/Litter

You May Also Like