A variety of factors contribute to producers missing target market weights, incurring discounts. Producers have adopted marketing strategies, such as topping pens, to help reduce economic losses from weight discounts at the processing plant.

December 15, 2012

A variety of factors contribute to producers missing target market weights, incurring discounts. Producers have adopted marketing strategies, such as topping pens, to help reduce economic losses from weight discounts at the processing plant.

Despite these efforts, producers are still missing target weights and suffering the consequential discounts.

One factor is the error of sampling methods used to estimate the mean weight of the population to determine the optimal time to top off finishing pens. The standard sample size is 30 pigs.

Researchers at Kansas State University determined the best method for selecting 30 pigs to improve the accuracy and precision of estimating the mean pig weight of the population.

Computer analyses generated 10,000 sample means for different sampling procedures on three different datasets. The four sampling methods evaluated were:

1. Taking a completely random sample of 30 pigs;

2. � Increasing the number of pigs per pen randomly selected from one to 15 pigs and increasing the number of pens until all pens in the barn had been sampled;

3. Selecting the heaviest and the lightest pigs (determined visually) from 15 pens and calculating the mean from these pigs; and

4. Calculating the median weight of the same 15 heaviest and lightest pigs.

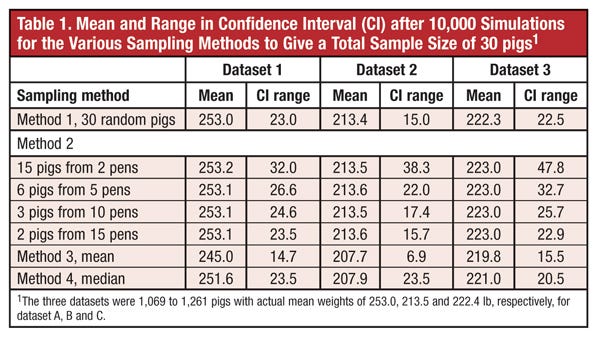

Taking a completely random sample of 30 pigs from the barn (method 1) resulted in a range in the estimate of the average weight of pigs in the barn that differed up to 23 lb. in the dataset (Table 1).

Within method 2, increasing the number of pens sampled while keeping the sample size constant reduced the upper and lower weight ranges in the groups. But it still resulted in a range in estimated weight of between 241 and 265 lb. (23.5-lb. difference) when only 30 pigs were sampled. Although the range was reduced by sampling more pens, it didn’t reduce it enough to make increasing the number of pens sampled a practical means of estimating mean pig weight of the barn.

Selecting the heaviest and lightest pigs in 15 pens and calculating the mean of the sample resulted in a reduction of the weight range (method 3).

Although precision of sampling was improved, accuracy of the sampling method decreased, with the mean of the 10,000 simulations up to 8 lb. lighter than the mean of the population.

Overall, selecting the heaviest and lightest pigs can provide a valuable method for improving the precision in estimating the mean of the population to be marketed. But adjustments to the sampling procedure need to be developed to improve its accuracy.

Researchers: C.B. Paulk, G.L. Highland, M.D. Tokach, J.L. Nelssen, S.S. Dritz, R.D. Goodband and J.M. DeRouchey, Kansas State University; K.D. Haydon, Elanco Animal Health, Indianapolis, IN. For more information, contact Paulk by phone (785) 532-1270 or e-mail [email protected].

You May Also Like