It used to be about all that pork producers worried about when it came to swine rations was availability of feed ingredients, and, of course, the prices of corn and soybean meal. But, currently, virtually all other key ingredients in swine diets also cost more, according to Joel DeRouchey, Extension swine nutritionist at Kansas State University (KSU).

It used to be about all that pork producers worried about when it came to swine rations was availability of feed ingredients, and, of course, the prices of corn and soybean meal. But, currently, virtually all other key ingredients in swine diets also cost more, according to Joel DeRouchey, Extension swine nutritionist at Kansas State University (KSU).

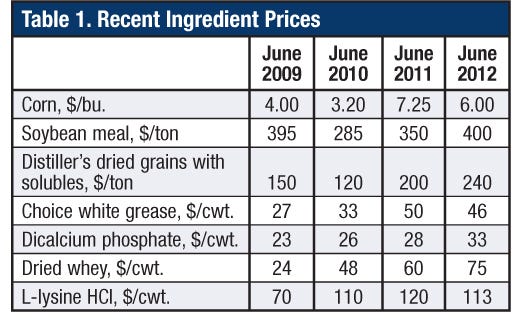

Those two main dietary components are still relatively high priced. However, as Table 1 illustrates, virtually all of the other key ingredients in a swine diet also cost more, according to Joel DeRouchey, Extension swine nutritionist at Kansas State University (KSU), in a presentation at World Pork Expo.

Here’s a rundown of key swine ingredients:

Spray-dried whey: It’s fed as a highly digestible lactose protein source in starter pig diets. Whey has skyrocketed in price from $24/cwt to $75/cwt over the last four years. Due to these price increases, some producers have cut back on lactose levels in nursery diets and others have eliminated it entirely from Phase 2 starter pig diets. In trials conducted by KSU, nursery pigs fed whey consistently outperformed control groups of pigs during this nursery phase.

But the fact remains, at a current price of $75/cwt., the added cost from feeding spray-dried whey in the Phase 2 diet (15 to 25. lb.) exceeds the weight gain benefit. However, most are very reluctant to reduce lactose levels to ensure pigs maintain improved growth rates during this stage of growth, DeRouchey emphasizes.

“The message is lactose economics are extremely tight right now. It looks like whey futures will ease going into the fall, but they are still going to be high. So the one thing we can do as producers is not feed more of these diets than what our diet budget calls for,” he explains. “Producers can get growth-performance benefits from feeding it longer than to 25 lb., but in our research it does not pay.”

Fat: Ten years ago, many producers fed 4-5% fat in every finishing ration all the way to market. That was when fat was priced 15-20 cents/lb. “But now we are dealing with fat (choice white grease) hovering around 50 cents a lb.,” DeRouchey says. Fat prices have risen at a greater rate than corn prices in recent years, and in most cases, it is no longer economical to feed it and many diets no longer contain it.

From 15 research trials, KSU developed a spreadsheet that shows that currently it is only economical to use fat in the first two finisher diets or to 120 lb., based on $6 corn, $400 soybean meal and 46 cents/lb. fat.

Most producers want to add fat during the summer to boost growth rates, DeRouchey points out. But when it gets hot, feed intake goes down. So to achieve maximum weights in summer when revenues are highest for the year, begin feeding fat to newly placed finishing pigs starting in March. However, feeding newly placed finishing pigs fat in summer is generally not needed, as their gains will improve once the weather turns cool in the fall when they are actually marketed.

Bakery byproducts: Candy, cookies and a variety of dried bakery byproducts serve as good energy sources for pigs, provided they are valued correctly. National Resource Council (NRC, 1998) guidelines suggest a standard book value for bakery byproducts of 11% fat, greater than corn’s 3.9%.

However, when KSU researchers looked at some bakery byproducts in mills, they discovered that fat content averaged only 6.4%; thus, knowing the nutrient value is critical to assigning the correct economic value.

Distiller’s dried grains with solubles (DDGS): Table 1 illustrates the changing economics of DDGS. “Right now (in early June), DDGS is about 112% of the price of corn and is higher priced than we have seen it in some time,” DeRouchey says.

That’s not to say that DDGS is not economical to feed. His data shows that there is a savings of about $1.71/pig when 10% DDGS is fed continually from 50 lb. to market, based on DDGS priced at $240/ton. “If we go to 30% DDGS in the diet, feed savings overall from 50 lb. to market increase to about $2.37/pig,” he adds.

Those returns are a far cry from the payback of one year earlier (June 2011). At that time, corn was $7.25/bu., soybean meal was $350/ton and DDGS was $200/ton. The price ratio of DDGS:corn was 77%.

Using that scenario, feeding 10% DDGS from 50 lb. to market resulted in a savings of $3.12/pig. That savings increased to $8.05/pig when 30% DDGS was fed from 50 lb. to market.

For DeRouchey, the bottom line is whether the smaller economic advantage of feeding DDGS today is worth feeding it at the higher levels, given that growth performance might be jeopardized.

Oil-extracted DDGS: Currently, a large number of ethanol plants are extracting corn oil from DDGS to separately market this energy product. That’s expected to reach 80% of the plants by the end of 2012, he predicts.

“What that means is the distiller’s grains we worked with in the past will not be the distiller’s grains that we will be working with in the future,” DeRouchey says.

From a product that the pork industry was finally starting to figure out how best to use, oil-extracted DDGS offers a product that has less energy and calories and 5-9% fat.

This change only adds to the uncertainty over product variability from different plants and different manufacturers that are processing DDGS at fat levels all over the board.

And that makes it incumbent upon producers to really determine the level of savings and performance afforded by oil-extracted DDGS before they decide whether it is worth it to feed it, DeRouchey concludes.

More information on swine nutritional programs available online from KSU can be found at www.ksuswine.org.

About the Author(s)

You May Also Like