Differences in financial acumen aren’t based on the size of the hog unit

January 18, 2011

Differences in financial acumen aren’t based on the size of the hog unit.

When it comes to providing a financial snapshot of pork producer clients, there is almost a shocking disparity in overall balance sheets, says Mark Greenwood of AgStar Financial Services, based in Mankato, MN.

“The biggest frustration for us is that some people have improved their balance sheets dramatically, while others haven’t,” he says. “And it is not a function of size, but rather a function of risk management and what I call cost and margin management.”

Those who have done well in this regard have enjoyed almost a $30/head profit for 2010 (through October, with some expected dropoff in November-December), while some other producers have merely broken even. Pork clients have probably averaged positive returns of $10-12/head for 2010, Greenwood relates.

Producer Differences

Greenwood says the top producers are more prepared for volatility than they have ever been. Besides always striving for greater efficiency, these producers have worked hard to rebuild their balance sheets and, overall, have become more financially sound by accomplishing two key things:

Financial reporting. Producers focus on good financial results that allow them to make sound management decisions. “We have producers who do a 12-month breakeven cost projection every day,” Greenwood says. “I recently visited with a client that literally knows down to a nickel what his breakeven costs are. The biggest thing we see with producers who struggle is that they don’t have good, accurate, timely financial data.”

Producers need to have monthly financial information on their overall business, either prepared by themselves or by a consultant. Amazingly, there are still a fair number of producers who don’t have a solid grasp of this information. Some are clients with a $6-7 million hog business, Greenwood reveals. This shortcoming makes it extremely difficult to provide continued access to capital.

Margin risk management. Over the years, the progressive producers have become really good at pork production. Now, they are doing a good job of managing margins as well.

“If you are a pork producer and raise a lot of your own corn, even if your cost of production for a bushel of corn is $4, there are opportunities to make $25/head profits today (mid-December) and for the next 12 months,” Greenwood says.

Even for a producer buying all of his major grain inputs — 2011 corn priced at $5.50/bu., soybean meal at $340/ton — total production costs of about $150/head, 12-month futures still show profits of $5-10/head, he says.

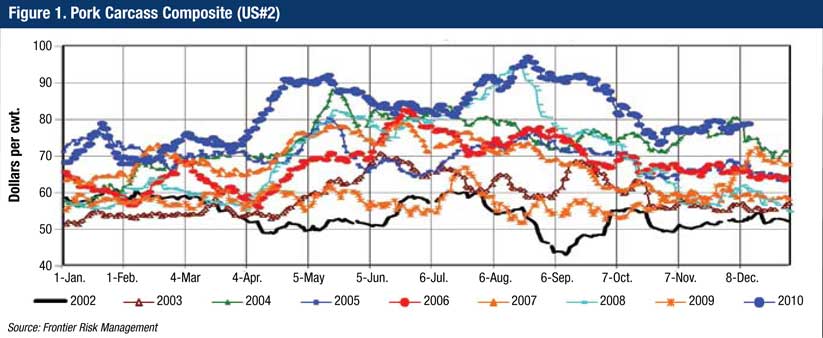

Looking ahead to 2012, corn may reach $7/bu., he says. But, price projections show hog futures touching the mid- to upper-$80s, meaning savvy producers who act in time will still be able to lock in profitable returns.

To get on a sustained track of profitability, producers must change their mindset, Greenwood stresses. Don’t wait to try and hit a home run when it comes to selling hogs. Rather, take the positive margins available.

“I understand how hard those marketing decisions can be,” he says. “It also takes a pretty good lender who understands that it is going to cost producers money to manage that risk. Educate your lender and have an open relationship with him/her on what your risk management positions are.”

The bottom line is that producers need to manage margins better. Realize that overreactions often bring poor results and are riskier than simply taking advantage of the positive margins that still exist in the market today.

Also, when you think crop prices are going down or hog prices are going up, you can manage margins by locking in a position on the futures market using some options strategies. You pay for the insurance coverage, but it can provide a little more upside in your return (margin) when the market goes up. Producers should constantly be adjusting their marketing plan to improve margins, he explains.

Part of that adjustment is realizing that the United States is part of a global market. Moves by China, for example, can impact the market, since they represent 50% of world pork production.

The meat trade can be another signal of how prices and margins are trending. For instance, wholesale pork cuts recently reached 10-year historical highs, which contrasts with the popular belief that prices are always bad, Greenwood states.

Securing Corn Supply

Looking at the overall hog enterprises of clients today, Greenwood challenges them to take steps to remove some of the volatility in their production model and make their business more valuable for the future.

“It might not mean owning a packing plant, but it might be controlling the cropland,” he explains. Some large hog clients have already gone to renting land over buying to keep their balance sheets liquid and flexible, while still securing the corn supply they need.

That rented ground can provide a place to incorporate hog manure which, in effect, lowers corn production costs by taking advantage of its fertilizer value.

Greenwood also says it is time to resurrect a challenge he first presented at the 2008 Minnesota Pork Congress: every pig owner should secure first right of refusal on their contract hog growers for all of the corn that they raise.

The agreement can be mutually beneficial. “I think you need to consider a program where at least you have access to the corn. If you are a contract grower and that pig owner doesn’t have corn to feed to his/her pigs, then he might not have pigs to place in those contract barns,” Greenwood points out.

Southern Producer Alignments

Producers have done an amazing job of using alternative feed ingredients, including distiller’s dried grains with soluble (DDGS), bakery products and wheat midds to counteract some of the impact of $5.50/bu. corn, Greenwood says.

But for producers in the Southeast, the challenge is more daunting because they are dealing with $6.30/bu. corn. “You just have to have a more aligned model in the Southeast, either a cost-plus agreement with packers or some type of price floor that doesn’t leave the producer shouldering all of the market risk,” he observes.

Virtually all southeastern pork producers have their own feedmills, so they can retain three to nine months storage to withstand wild swings in the grain market. Eastern Corn Belt producers are nearly in the same boat.

In the future, even Midwest producers who don’t own their own feedmills should consider entering into a contract with a neighboring producer who owns a mill and has excess capacity. Aligning with a cooperative or feed elevator is another option. No longer can producers afford to pay an elevator storage charge of 10-15 cents/bu.

Production, Health Advances

As producers continue to focus on production efficiencies, sow performance will likely lead the way, but Greenwood predicts advances will come slower in the next decade.

Many producers still fall short in mortality management. In preweaning and finishing, 15-20% of production is still being lost, he says. “It is significantly better than it used to be (mid-20%), but there is still a huge opportunity within those parameters to lower your production costs,” he adds.

And as big a skeptic as Greenwood admits to being, air filtration of sow farms has proven to be an effective deterrent to infection with porcine reproductive and respiratory syndrome (PRRS) virus. It costs about $200/sow to put in an air filtration system, vs. $300/sow for a PRRS break. Some farms in hog-dense regions suffer multiple breaks annually.

Greenwood advises the industry to take the next couple of years to perform a more in-depth analysis of the technology to more accurately pinpoint the return on investment.

Succession Planning

Some of the brightest minds in the pork industry who are age 50-plus have taken steps to transition their hog operation to the family’s next generation to ensure its survival. “I look at a lot of the businesses that we work with, and there are a lot of owners who are older than 50, so I think the biggest thing the industry needs to address is what is going to happen in the next 10-20 years and who will run the pork industry,” he says. Succession planning needs to be addressed, and it can be a 5- to 10-year process, he reminds.

You May Also Like