October 15, 2013

Group-housing systems allow sows freedom to: (1) move around and explore their environment, (2) perform normal positive and negative social interactions with their pen-mates, (3) choose an area for urination and defecation, and (4) choose an area for sleeping.

However, in poorly designed and managed indoor group-housing systems, there is great potential for very poor sow welfare. This can lead to problems such as lameness, injury and reduced body condition if the sows have to fight for access to feed, have difficulty avoiding aggressive encounters or do not have an appropriate place to rest.

The main criteria for choosing a certain group-housing system will most likely involve an evaluation of the investment costs, ability of both the facility and management to maintain a high level of the sow’s health and welfare, ease of performing work tasks, labor requirements, feeding system, overall simplicity of the system and reproductive performance of the sows.

Many pork producers will be making decisions as to whether they should: (1) retrofit an existing individual sow breeding-gestation stall barn into sow group-housing, (2) construct a new breeding-gestation barn for group-housing sows because of too many compromises and remodel the existing barn for additional farrowing, (3) stop farrowing sows and convert buildings into nursery and grow-finish buildings, or (4) completely exit the pork business because legislation mandates group-housing sows and their facilities are in need of major repair or substantial remodeling.

Most likely there will be some degree of compromise in requirements for group housing sows when retrofitting existing stall gestation barns. As a general rule, if the cost of remodeling exceeds two-thirds the cost of a comparable new facility, it is wiser to proceed with construction of the new building. All group-housing methods will result in some level of aggressive interactions between sows at time of mixing and feeding.

Keep the most in-depth pork production information available at your fingertips! Download our Blueprint app today.

Designing a system to group-house gestating sows is a complex issue that involves engineering, animal science, animal welfare, animal behavior and economics. Some decisions have to be made without scientific evidence and verification at the farm level.

Listed below are design requirements that are common to all sow group-housing systems:

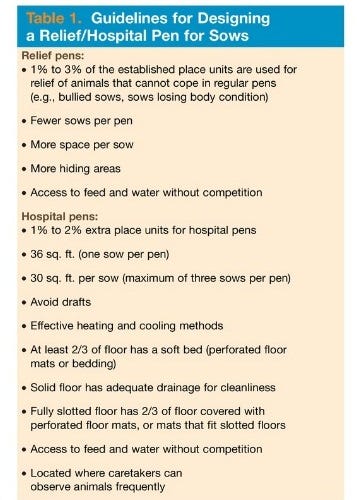

Relief pens.When housing sows in groups, it is inevitable that a few sows will get sick, get injured or be bullied by other sows in the group. The design, number and management of relief/hospital pens will depend on the individual farm and reason for sows being removed from the main group. Table 1 provides guidelines for designing relief/hospital pens.

Heat-check boars.Boars should be housed away from sows to be heat-checked. Housing boars too close to estrous sows can cause the sows to be non-receptive to boar stimuli. Worker safety needs to be considered when moving and handling heat-check boars in wider alleys and within sow pens.

Space allowance.The determination of space per sow is a critical aspect when designing a barn for group-housing sows. Space is required for body postures of sows (standing, sitting, lying), changing of postures, social interactions (establishment of hierarchy, avoidance of potential aggressors, escape from an attack, estrous activities), and normal movements for feeding, drinking, defecating and urination. Making specific recommendations for space per sow is complex because space interacts with many aspects of the sow’s environment (e.g. heat-stress, number of sows per pen, variation in body size of sows, housing system, and adding small groups into larger groups at different times). Insufficient space can affect productivity, behavior and welfare. In general, the minimum space per sow for group-housed animals is 15 to 18 sq. ft. for gilts, 19 to 24 sq. ft. for mature sows and 18 to 23 sq. ft. for mixed (gilts and sows) groups. For groups of 10 or less animals, the upper value would be used and the lower value would apply to groups greater than 40 animals.

Pen design.Careful attention needs to be given to the location and design of the eating, drinking, dunging, lying and walking areas to reduce aggressive interaction among sows within the pen. For example, the minimum distance between the back of two rows of free-access stalls is 7 to 10 ft. in Europe (See Figure 1). A wider alley enables sows to pass each other without aggression. Partitioning the pen space with short walls (creating resting bays) can provide a method for sows to avoid aggression and for subgroups to have secure lying areas.

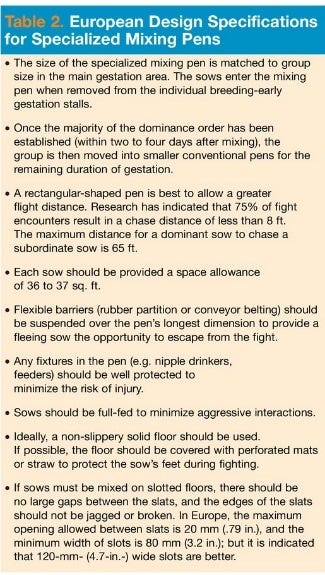

Mixing pens. In North America, specific requirements for designing pens to mix sows have not been vastly studied and verified at the farm level to evaluate methods to protect the health and welfare of sows. Because of the large amount of space required per sow at the time of mixing (36 sq. ft.), the use of a specialized pen to establish social dominance is worthy of consideration. European design specifications for specialized mixing pens are indicated in Table 2.

Feeding method.The method by which group-housed sows are fed has been a major concern to pork producers. Because today’s sows farrow large litters and produce large volumes of milk, they need to enter the farrowing facility in excellent body condition. The nutrient requirement of each sow in a group of sows can be quite different due to parity, body weight, stage of gestation, backfat, overall body condition and room temperature. The only way to meet each sow’s nutrient requirements is to use individualized rationing without competition during eating. Producers need to decide whether they want to feed their sows in a non-competitive or competitive feeding system.

Non-competitive feeding systems. There are two non-competitive feeding systems available: electronic sow feeders or gated free-access stalls.

Electronic sow feeders.The ESF system has control over individual feed intake because the manager enters a personalized feed program for the sow into the system.

Free-access stalls.Thelockable free-access stalls with mechanical feed drop boxes allow the caretaker to control the amount of feed that a pen of animals consumes, but not the specific amount of feed that each individual sow should be given. The caretaker does not know which sow will be in which stall at feeding. Thus, the caretaker divides the total amount of feed allocated to the pen evenly among the sows. The caretaker should form groups of sows based on desired feeding level by penning thin sows together, fat sows together and sows of similar body size together. If the free-access stalls have a front alley, thin sows can be quickly hand-fed additional feed by identifying thin sows with a stock marker.

Competitive feeding systems. Basically, there are two types of competitive feeding methods: (1) feeding sows without any protection from pen mates (feeding on the floor or feeding in a trough without divisions), or (2) feeding sows with partial protection from pen mates (use of head- and shoulder-length partitions or full-body-length partitions without rear gate).

Dominant sows eat more feed and gain more weight than subordinate sows, especially when feed is dispensed once per day on the floor. To diminish the dominant-sow effect when floor feeding, producers have partitioned the floor into bays, installed two feed lines, dropped feed into each bay at several locations, dropped feed a few seconds apart between the two feed lines, and dropped feed several times per day at different time intervals.

When feeding sows with a partial partition between sows, fast- eating sows will try to steal feed from other sows, especially when the daily allotment of feed is fed with a single drop. To help prevent fast- eating sows from stealing feed, trickle feeding has been implemented. Most trickle feeding systems have a feed box for each sow within the pen. The feed box is filled with a top auger. The feed box is designed to meter feed into a second auger located at the bottom of the feed box. The second auger rotates very slowly when dispensing the feed. The rate of dispensing feed ranges from 0.17 to 0.44 lb. of feed (80 to 200 grams) per minute.

With competitive feeding systems, the caretaker should form groups of sows based on desired feeding level by penning thin sows together, fat sows together and sows of similar body size together.

Number of sows per pen. A wide range in number of sows per pen has been utilized on sow farms. The decision is influenced by overall number of sows in the herd, size of the breeding groups, feeding system, size of sub-groups when considering feed intake (gilts, fat sows, thin sows, sows of similar body size), and size of sub-groups when considering competition (small pen, large pen). These decisions will influence the overall size of the barn.

Weaning-breeding-early gestation stalls. The advantages of using individual sow stalls for weaning, breeding, and the first 35 to 42 days of gestation include: (1) sows do not fight and injure each other after weaning, (2) sows can be full-fed from weaning to breeding, (3) daily boar stimulation can be easily accomplished, (4) daily estrous detection can be easily accomplished, (5) artificial insemination can be easily performed, (6) sows have less stress during implantation of embryos, and (7) additional feed can be provided to first litter, second litter and thin sows.

Highly prolific sows are nursing 12 to 14 piglets, producing 2.8 to 3.8 gallons of milk per day, and may have lost a substantial amount of body weight during lactation. For sows to regain body condition, it is best to individually house sows from weaning to 30 days of gestation. Sow body condition can influence the effect of feeding high levels of feed after mating on embryonic survival.

If sows are in good body condition, high feed intake during the first 30 days of gestation can increase embryonic mortality. If sows are in thin body condition, embryonic mortality is decreased by increasing feed intake during day 3 to 30 of gestation. A study in the Netherlands (Hoving et al., 2011, J. Anim. Sci. 89:3542-3550) found that feeding first and second parity sows 7 lb. per day from day 3 to 30 of gestation improved sow body weight recovery and increased subsequent number of piglets born alive per litter compared to sows fed 5.5 lb. per day (14.4 vs 12.6 piglets). However, farrowing rate was numerically lower for sows fed 7 lb. per day (76.6% vs 89.8%). The fecundity index (farrowing rate x number of pigs born alive) would be 1,131 pigs per 100 sows bred for sows fed 5.5 lb. per day vs. 1,103 pigs for sows fed 7 lb. per day.

Training pen. When using an ESF system, space is needed for a pen to train replacement gilts.

Vulva biting. The welfare issue of vulva biting can be regularly observed in sows kept in pens and fed on both sides of the pen without protection. Vulva biting may or may not be a problem when using correctly designed electronic sow feeder stations in combination with an optimal layout of the floor plan for sow movement within the pen.

Considerations when retrofitting an existing facility

Method of feeding and the existing type of floor are key considerations when retrofitting an existing barn into group-housing of sows. It is more challenging to retrofit a traditional individual gestation stall barn with a partially slotted floor than a barn with a totally slotted floor. Some of the factors that need to be considered when retrofitting a gestation barn with a partially slotted floor are indicated below.

Feed trough. Decisions need to be made as to whether the existing feed trough can be used, or if it needs to be capped or removed.

Feed lines. Decisions need to be made about the use, location and moving of existing feed lines. If sows are floor fed, the feed drop boxes should be located where caretakers can easily work in the pen without hitting their head. Installing extra feed drops per pen allows for additional feed to be dropped during last three weeks before farrowing when sows are being floor-fed.

Solid section of floor. The existing solid floor areas may limit retrofitting options without excavating the floors and (or) manure pits. The floor needs to be evaluated to determine if it is too rough or too slippery, or if it is located in the correct area of the pen. The floor can be capped if needed.

Slotted section of floor. The existing slats need to be evaluated for sharp or damaged edges; broken slats in need of replacement; proper width of gap between slats to prevent the risk of sows catching their claws and (or) twisting their legs during aggressive interactions; adequate area within the pen for defecation and urination; and slat location within the pen.

Ventilation, heating and cooling. The existing ventilation, heating and cooling system has to be evaluated to determine whether it is sufficient or if modifications are required for the number of animals in the retrofitted barn. Consideration will need to be given as to whether the air inlets are properly located so as to not create draft on solid areas of the pen. Sows will defecate and urinate in drafty areas.

Logistics of retrofitting. A decision has to be made as to the process used to retrofit the barn. Can the process be accomplished in stages? Does the entire barn need to be retrofitted at the same time? Does the farm have to be depopulated? Can an off-site facility be found to temporarily house sows? Can reproductive performance and biosecurity be maintained when housing sows off-site?

Comparative retrofitting investment costs

Each farm will need to make their own cost comparison between the different types of group-housing systems that might be the best for their situation. The comparison between group-housing systems is generally made on the retrofit capital cost per sow housed in the facility.

Although productivity might be different between group-housing systems, management procedures play a key role in the success of the group-housing systems. Farms that have retrofitted their sow buildings normally only use one type of sow group-housing system; thus, there is no comparison between two different types of sow group-housing system on productivity.

Read more sow housing stories:

You May Also Like