March 5, 2014

Rising propane costs have many pork producers wondering if it would be more profitable to turn down the thermostat and increase available feed. This can be particularly true for pigs that are early weaned, which have higher temperature requirements than most pigs.

"Typically when we hear the phrase "food vs fuel," it's in regards to ethanol production. However, with the recent increase in propane costs the same could be said for pork production," said Bob Thaler, SDSU Extension Professor & Swine Specialist. "The pig is incredibly adaptive to its environment, and can compensate for changes in thermal environment by a variety of ways, the biggest probably being changes in feed intake."

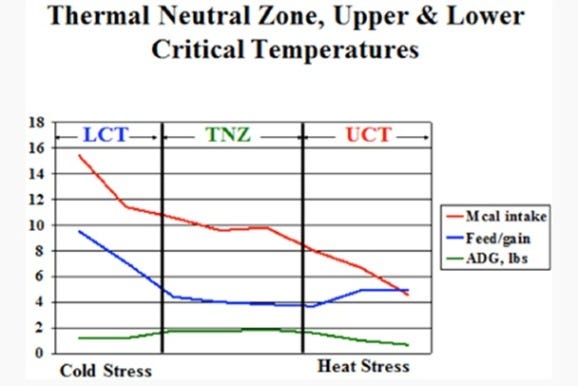

As can be seen in the graph below, Thaler showed how a pig's feed intake is directly related to the temperature of the pig's environment. He explained that as the temperature decreases, a pig will eat more feed in order to generate more body heat to stay warm.

"As long as gut fill isn't an issue, daily gains should be normal, but feed efficiency will suffer because the extra pounds of feed are going into heat production and not into body growth," he said.

Basically, Thaler said the choice comes down to whether the extra calories from feed are cheaper than the cost of the propane needed to keep the pig in its thermal neutral zone. With corn at $4 per bushel, soybean meal at $450 per ton and propane close to $4 per gallon, utilizing more feed calories is something he said producers should at least consider.

A collaborative trial done by South Dakota State University, the University of Minnesota, the University of Nebraska and the University of Missouri-Columbia, looked at the effects of reducing nocturnal temperature of early-weaned pigs (17-21 days) in colder months.

Like what you’re reading? Subscribe to the National Hog Farmer Weekly Wrap Up newsletter and get the latest news delivered right to your inbox every week!

The first week post-weaning, both rooms were kept at identical temperatures. However, one week after weaning, the temperature in the Reduced Nocturnal Temperature (RNT) room was dropped 10 degrees from the Control (CON) between 7 p.m. and 7 a.m., and then returning to CON temperatures from 7 a.m. to 7 p.m. Pig performance and utility usage were measured throughout the trial. There were no differences in pig gain, feed intake, or feed efficiency for the 28-d period, but heating fuel use (BTU per pig) was reduced by 17.4 percent and Kilowatt hour per pig was reduced by 10.7 percent for the pigs in the RNT treatment. Using $5 per gallon for heating fuel price and $.08 per kilowatt hour, this equates to a saving of $2.90 per pig in heating fuel and $.05 per pig in electricity. This results in a total saving of $2.95 per pig in utility cost without affecting pig performance.

Typically, room temperatures for early weaned pigs start at approximately 85F and then decrease to 72F throughout the 4-6 week nursery period, so there's a good opportunity for savings.

The other area where temperature reductions could work is in gestation barns, explained Thaler.

"Sows are limit-fed during gestation to maintain proper body condition so dropping the thermostat slightly should not hurt sow performance as long as there is an increase in feed offered to the sows," he said.

Thaler referenced work by Verstegen and Curtis conducted in the late 1980s which demonstrated that decreasing room temperature by 4 degrees below thermoneutral conditions will require approximately an extra half pound of feed per day per sow.

With gestation feed at $200 per ton, that would be an increase in feed cost of $.05 per sow per day.

"Producers would then need to balance that cost against the propane savings in their individual barns. Management also plays a role in this decision. To properly adjust all the feed drop-boxes takes time, so that is an additional cost that also needs to considered in the equation," Thaler said.

In general, he said it would probably make more sense to adjust feeding levels in November when we're going into winter than at the end of February where we are going into a period of warmer weather for gestating sows.

"Higher propane costs do present a challenge to pork producers, but there are things producers can do to compensate for it," he said.

Thaler added that management tools, like reducing nursery room temperature at night, will not affect pig performance but can save producers almost $3 per pig in utility costs. Going into an extended cold period, producers should also weigh the costs and benefits of lowering gestation barn temperature while increasing feeding level.

You might also like:

Many Factors are Working Together to Impact Pork Supply

You May Also Like