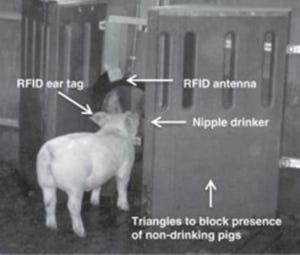

Hog Welfare

thumbnail

Farming Business Management

Ag Committee leaders release dueling Farm Bill proposalsAg Committee leaders release dueling Farm Bill proposals

Legislative Watch: House bill includes a provision stopping states from regulating livestock production outside their borders; USDA trade mission aims to open India to American goods.

Subscribe to Our Newsletters

National Hog Farmer is the source for hog production, management and market news

.jpg?width=300&auto=webp&quality=80&disable=upscale)